LUISA KOSTER

Big Title

A SPECULATIVE EXPLORATION OF SECOND LIFE GLACIER PROTECTION MATERIALS

Repurposing Glacier Covers is an exploratory research project investigating how used glacier protection covers could be given a second life before entering recycling streams.

Rather than proposing an implementable solution, the project explores the material’s properties and circular potential to question how industrial waste could be repurposed to raise awareness around resource use and circular economy principles.

ROLE

Design Researcher:

Material exploration

Circular thinking

Speculative framing

CONTEXT

Self-guided project

Short exploratory project

Focus on material reuse

3 Days Project

Spring 2022

METHODS

Research

Desk research

Material research

Circular economy research

Exploration

Material observation

Concept development

Speculative design framing

TEAM

Luisa Koster:

Design Researcher

OUTCOME

Exploratory second-life product idea developed from used glacier protection covers, translating material research into tangible applications.

CONTEXT

Glacier protection covers are used in the Swiss Alps to slow down glacial melting.

The textile sheets are made from tear-resistant, lightweight polypropylene and are typically replaced after around five years of use.

While their contribution to climate protection is widely discussed, the question of what happens after their removal remains largely unaddressed.

Despite being fully recyclable, many used glacier covers are taken off the mountains and treated as waste, without considering their potential beyond disposal.

GLACIER MELTING

GLACIER COVERS (PP)

END OF USE

UNADDRESSED QUESTION:

What happens after removal?

CHALLENGE

Glacier protection covers are designed as high-performance materials for extreme alpine conditions. After five years of exposure to weather, UV radiation, dirt, and mechanical stress, the covers no longer meet the technical requirements needed for glacier protection and must be removed.

Once taken off the glaciers, the covers are difficult to reintegrate into existing material flows. They are often heavily soiled, fragmented, and logistically complex to collect and transport from remote alpine locations. As a result, reuse is rarely considered, and the material is typically classified as waste, even though it remains structurally durable and fully recyclable.

PROBLEMS

Functional limitation

Once exposed for several years, the covers no longer fulfill the performance standards required for glacier protection.

Material condition

The covers are heavily soiled, weathered, and partially damaged, making immediate reuse unlikely without additional processing.

Logistical complexity

Collecting and transporting large textile surfaces from remote alpine areas is costly and difficult to organize.

Lack of responsibility

There are no established systems, stakeholders, or processes in place to manage the material after removal.

Default waste classification

Without alternative pathways, the covers are categorized as waste despite their remaining material value.

Research Question:

How can the material value of glacier protection covers extend beyond their first use?

RESEARCH

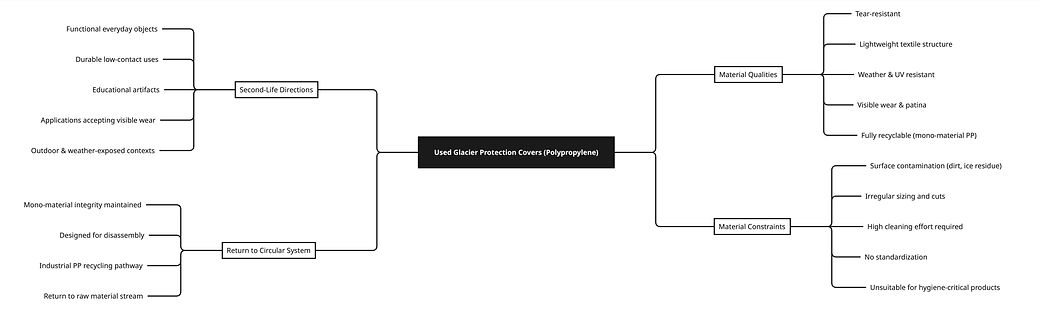

The research focused on understanding glacier protection covers as a material system after their initial use. It examined how the covers are used, removed, and classified, as well as where material value is lost once their protective function ends.

The aim was not to optimize glacier protection, but to identify gaps in the material lifecycle between use and disposal.

METHODS

Desk Research

Glacier protection practices, material lifecycles, replacement cycles, and waste handling in alpine contexts.

Material Research

Properties of polypropylene (PP), including durability, weather resistance, wear, and recyclability after long-term exposure.

Lifecycle Analysis

Understanding the transition from use phase to removal, disposal, and recycling of glacier protection covers.

System Mapping

Mapping the material flow to identify gaps between functional end-of-use and recycling.

KEY INSIGHTS

-

The end of the glacier covers’ protective function is treated as the end of their lifecycle.

-

Despite visible wear, the material remains structurally durable and recyclable.

-

After removal, there is no defined responsibility or system managing the material.

-

The transition between removal and recycling is undefined and overlooked.

-

Material value is strongly influenced by context and narrative.

DESIGN CRITERIA

Insight

The end of the glacier covers’ protective function is treated as the end of their lifecycle.

Design Criterion

The design must address the material lifecycle beyond its initial protective use.

Insight

Despite visible wear, the material remains structurally durable and recyclable.

Design Criterion

The design should preserve and highlight existing material qualities rather than masking wear.

Insight

After removal, there is no defined responsibility or system managing the material.

Design Criterion

The design must function independently of existing glacier protection operations.

Insight

The transition between removal and recycling is undefined and overlooked.

Design Criterion

The design should explore a second-life phase before the material enters recycling.

Insight

Material value is strongly influenced by context and narrative.

Design Criterion

The design should create a new context that communicates the material’s origin and value.

DESIGN DECISIONS

Based on the research and material exploration, the following design decisions were made to ensure that any proposed direction remains realistic, circular, and material-driven rather than solution-driven.

Design Criterion

The design must address the material lifecycle beyond its initial protective use.

Design Criterion

The design should preserve and highlight existing material qualities rather than masking wear.

Design Criterion

The design must function independently of existing glacier protection operations.

Design Criterion

The design should explore a second-life phase before the material enters recycling.

Design Criterion

The design should create a new context that communicates the material’s origin and value.

Design Decision

The glacier protection covers were treated as the starting point of the design process, not as waste.

Design Decision

The material’s weathered surface was preserved and treated as a defining characteristic.

Design Criterion

A new use context was defined that starts only after the covers are removed from the glacier.

Design Criterion

The design exploration focused exclusively on uses that extend the material’s lifespan before recycling.

Design Criterion

The material’s origin and previous use were intentionally kept visible within the new use context to gain attention about glaciers melting.

INTERVENTION

The intervention explores how the material value of glacier protection covers can extend beyond their first use by introducing a clearly defined second-life phase.

Rather than proposing a single optimized solution, the intervention applies the previously defined design decisions to test how the material can move through an extended lifecycle, from removal to second use and back into recycling.

EXTENDED MATERIAL LIFECYCLE

The following lifecycle illustrates how used glacier protection covers can transition from their original function into a second-life application before re-entering the recycling system.

Unlike the original glacier blanket lifecycle, which ends after removal and direct recycling, this intervention adds a structured post-use phase. This phase focuses on preserving material value through minimal processing, functional reuse, and intentional visibility of the material’s origin.

By extending the lifecycle, the material remains in active use longer, while maintaining its ability to return to industrial recycling at the end of its second life.

INTERVENTION JOURNEY

ANSWERING THE RESEARCH QUESTION

Research Question

How can the material value of glacier protection covers extend beyond their first use?

Answer through the intervention

By introducing a defined second-life phase between removal and recycling, the intervention shows that material value can be extended through functional reuse, minimal processing, and contextual reframing, without altering the material’s recyclability or original purpose.

WHY A REUSABLE SHOPPING BAG

The second-life phase was explored through a reusable shopping bag, as it aligns with both the material properties and the intended lifecycle extension.

The bag supports repeated, long-term use, tolerates visible wear, and does not require hygiene-critical standards. As an everyday object, it introduces the material into a consumer context where use and consumption are closely linked.

By carrying the bag while shopping, the material’s origin remains present during an activity associated with consumption and environmental impact, turning the object into a subtle reminder of the relationship between everyday choices and glacier melt.

EFFECT

For Consumers

Creates awareness of material lifecycles by turning glacier protection covers into an everyday object that links consumption with environmental impact.

For Businesses

Demonstrates how extending the use phase of existing materials can reduce dependency on virgin resources and energy-intensive production processes. By adding a second-life phase before recycling, material value is retained longer, enabling businesses to align circular principles with storytelling, differentiation, and sustainability objectives.

For Urban Development

Reduces resource extraction and energy use by delaying recycling and avoiding the production of new materials. Keeping high-performance materials in circulation longer lowers overall material throughput and can reduce emissions, especially when processing and reuse are handled locally.

Open Question:

Who could be potential adopters or buyers of second-life products made from glacier protection covers, and how could such initiatives be financially viable while keeping production local and circular?